Switch-Rated Devices Maximize Safety, Reliability, and Cost Efficiency

Make the switch from risky pin and sleeve connectors and restrictive hardwiring. Enable quick, hassle-free changeouts by implementing Switch-Rated plugs and receptacles from MELTRIC.

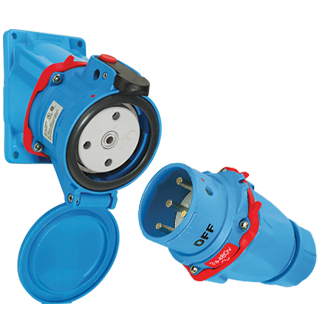

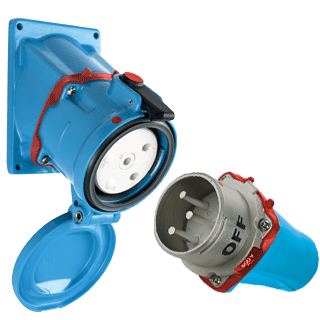

MELTRIC DSN and DS Series Switch-Rated plugs and receptacles combine the safety of a switch with the convenience of a plug and receptacle in one reliable, cost-effective device.

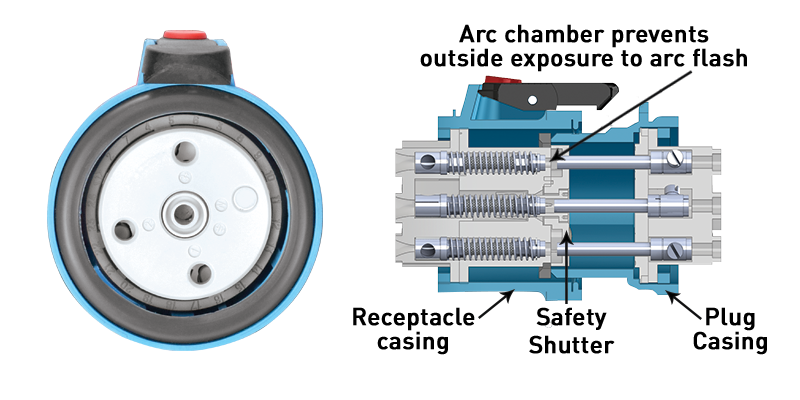

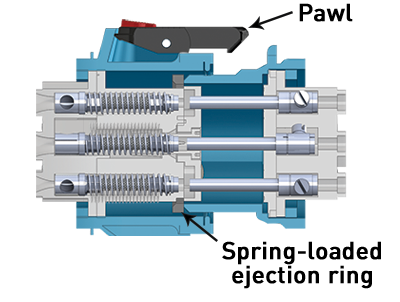

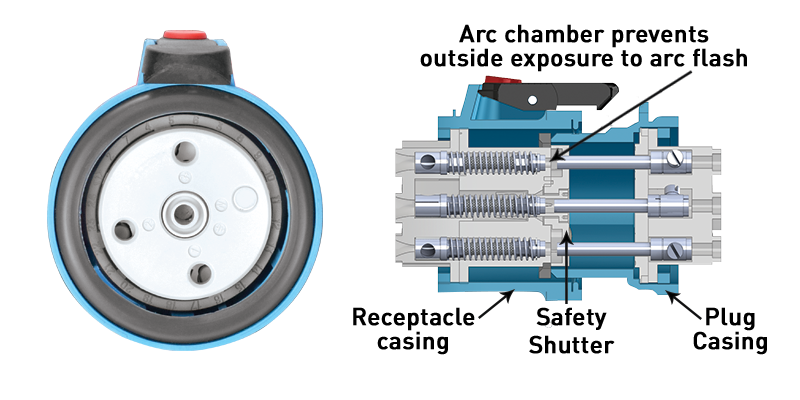

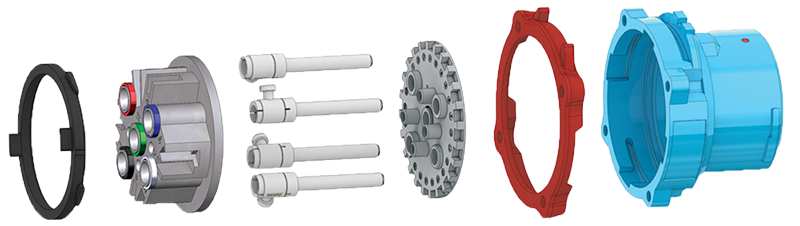

DSN and DS devices are engineered with DECONTACTOR® technology. This technology provides spring-loaded, silver-nickel butt contacts, push button disconnection, enclosed arc chambers, and dead-front construction with a safety shutter to ensure user safety, code compliance, and operating cost benefits that are not possible with other devices.

MELTRIC Switch-Rated Device is Equivalent to the Combination of a Pin and Sleeve Connector and Disconnect Switch

MELTRIC Switch-Rated plugs and receptacles meet or exceed the safety and functionality of pin and sleeve devices. This is achieved by combining the functionality of a disconnect switch with the usability of a pin and sleeve device.

MELTRIC offers the unique opportunity to replace one of your existing pin and sleeve devices from a competitor with a product from our DS or DSN series of devices. To take advantage of this offer please, CLICK HERE. This offer is risk-free and cost-free!

-if you are ready to buy now-

MELTRIC Devices are Replacements for Electrical Connection Devices and Pin and Sleeve Power Connectors from:

Molex | Hubbel | Leviton | Eaton | Russelstoll | Arrow Hart

Switch-Rated Brochure

Download our Switch-Rated brochure for a deep dive into Switch-Rated safety and how it can help you.

Make the Switch to Switch-Rated and Enjoy the Benefits of Decontactor™ Technology

Ensure User Safety

Protect workers from live parts and arcing and safely connect and disconnect under full load. More...

Simplify NFPA 70E Compliance

Ensure a safe work environment without the need for cumbersome PPE. More…

Easily Meet NEC Line-of-Sight Disconnect Requirements

With UL/CSA switch ratings for branch and motor circuit switching, DS and DSN series products are an approved line-of-sight disconnect switch. More…

Improve Reliability

Spring-loaded silver-nickel butt contacts maintain high conductivity for thousands of operations, even in harsh conditions. More…

Reduce Changeout Downtime by up to 50%

Technicians can safely make and break connections with plug and play simplicity on motors or other equipment connected with MELTRIC Switch-Rated plugs and receptacles. More…

Total Cost Reduction

Reduce equipment, installation, maintenance, and operational costs. More…

Ranges

- UL/CSA listed

- 20-150A, 600VAC, .75-75 hp

- Type 4X/IP69/IP69K environmental ratings

- Poly and metal (100A, 150A only) casings

- Add up to 6 pilot contacts

- UL/CSA listed

- 20-200A, 600VAC, .75-100 hp

- Type 3R or 4X/IP69/IP69K environmental ratings

- Poly and metal casings

- Add up to 6 pilot contacts

Key Features

MELTRIC Switch-Rated plugs and receptacles are listed for “Branch Circuit Disconnect Switching” and “Motor Circuit Disconnect Switching.” Models are available with branch circuit switch ratings from 20 to 200A and with motor circuit switch ratings from .75 to 200 hp. Models up to 100A and 50 hp are also rated to withstand and close into a 100kA short circuit, when protected with RK1 fuses.

MELTRIC DS and DSN Series are performance tested and listed to UL 2682, which is the standard specifically for Switch-Rated Plugs and Receptacles. It includes more severe testing than the standards for ordinary pin and Sleeve or twist lock devices require. To obtain both the branch circuit and motor circuit switch ratings, the same device must pass the following sequence of electrical performance tests in order:

HP Locked Rotor Overload Test

50 operations @ rated voltage and amperage that is 600% of the motor FLA for the associated hp rating, with a power factor of 0.5 or less.

Temperature Rise Test

Performed @ rated current with a maximum rise of 30°C permitted

Electrical Endurance

6000 operations @ rated voltage and rated amperage, with a power factor of 0.8 or less

Other required performance tests including, resistance to arcing, voltage withstand @ 3000V, and short circuit make and withstand tests are performed on separate devices.

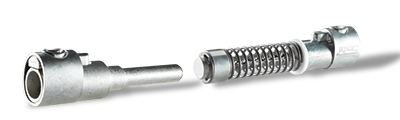

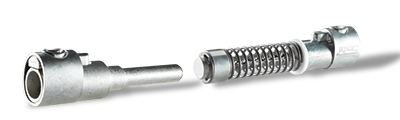

Spring-Loaded Butt Contacts Provide for Thousands of Consistent and Reliable Connections

MELTRIC Switch-Rated plugs and receptacles use spring-loaded, butt-style contacts similar to those used on contactors and switchgear. Their end-to-end mating provides a stable connection. The spring-loading delivers optimal contact pressure, and the integrity of the electrical connection is maintained over thousands of operations.

- Spring-loaded butt contacts automatically compensate for manufacturing variations, eliminating contact mating and connection quality problems caused by the dimensional variations of other contact designs.

- End-to-end mating eliminates the effects of wear inherent with sliding contacts.

- Consistent spring pressure eliminates overheating caused by poor contact force.

The performance and design advantages of spring-loaded butt contacts make them a superior choice for providing consistently safe and reliable connections.

Silver-Nickel Contact Material Provides Superior Conductivity

MELTRIC uses solid silver-nickel contact surfaces on its Switch-Rated plugs and receptacles. The contacts’ 85% silver and 15% nickel composition combines the durability of nickel with the excellent conducting properties of silver.

Silver-nickel contacts provide significant advantages over the brass materials used on most other types of plugs and receptacles:

- Silver-nickel maintains low contact resistance and superior electrical properties even after oxidation and tarnishing.

- Silver-nickel withstands arcing very well and only welds at extremely high pressure and temperature.

- The hardness of nickel gives the silver-nickel contacts excellent wear resistance.

- Silver-nickel performs well in and withstands wet and corrosive environments.

The combination of silver-nickel contacts with a spring-loaded butt-style design makes the contacts ideal for repetitive making and breaking of connections under load.

Limitations of Brass as a Contact Material

- Brass is not arc resistant, so it is not suitable for repeated making and breaking under load.

- Brass is a soft material and wears rapidly, degrading the operational characteristics of the contact.

- Brass oxidizes easily, preventing it from performing well in wet or corrosive environments.

- The contact resistance of brass increases rapidly due to tarnishing that occurs during normal use.

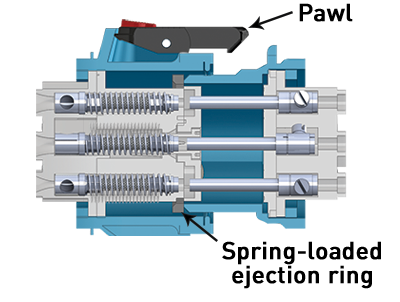

MELTRIC uses a spring-loaded ejection system to provide a quick and secure separation of the contacts during disconnection of the circuit. The quick break mechanism drives the contacts open in 15 ms or less, minimizing internal arcing and its impact on the contacts.

MELTRIC Switch-Rated devices disconnect the circuit simply by pushing the OFF button. This automatically breaks the connection and ejects the plug to the OFF position. The plug can then safely be removed by rotating it 30° counterclockwise and withdrawing it.

Dead Front Eliminates Hazards posed by Exposure to live parts or Arcing

Drawing an arc during plug removal is an inherent hazard with traditional pin and sleeve and twist-type devices. By contrast, MELTRIC Switch-Rated devices isolate the making and breaking of the contacts in an enclosed arc chamber. The plug contacts are deenergized and isolated from live parts before the plug can be physically removed.

When the receptacle’s OFF button is pushed, its spring-loaded operating mechanism instantly opens the contacts to break the circuit and ejects the plug to its OFF position. The quick (15 milliseconds) breaking of the contacts minimizes arcing; any arcing that does occur is safely contained within the internal and enclosed arc chamber.

In the OFF position, the plug contacts are dead and separated from live parts by a safe distance. Isolated and inaccessible to users, all contacts are fully contained within an enclosure formed by the plug’s skirted casing and the receptacle’s casing.

The rotation of the plug required prior to its removal from the receptacle automatically closes and locks the safety shutter. This ensures that potential arc paths and access to live parts are blocked before the plug can be removed. There is no possibility of drawing an arc. Hazard Eliminated!

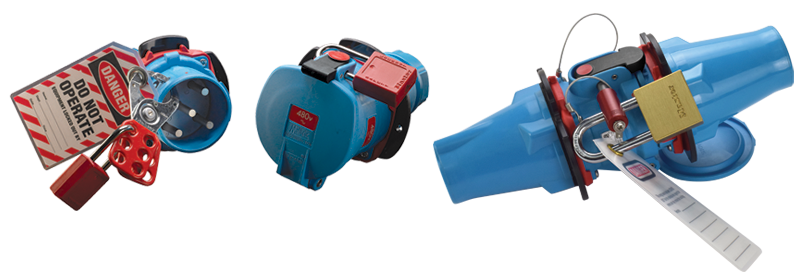

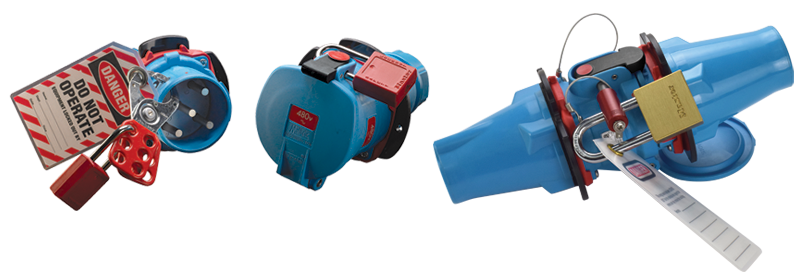

Lockout or Lock Together

All Switch-Rated devices include standard provisions on the plug that allow users to perform lockout/tagout by simply inserting a lock through an existing hole on the device. The user only needs to provide the lock – no additional mechanisms are required.

Simple lockout provisions for the receptacle are also provided as an option on the DS and DSN Series. A locking pin fits snugly in a circular opening through the pawl and prevents the pawl from operating. Various sizes locks and lockout hasps can be used with the locking pin to complete the lockout.

The lockout provision on DS and DSN Series receptacles can also be used to lock the plug and receptacle together. This can be an important consideration in public or other critical areas where it is important to prevent unauthorized disconnections.

Spring-Assisted Terminals Provide Superior Conductor Connections

On traditional plugs and receptacles, the loosening of terminal screws is a common cause of failure. MELTRIC devices have patented, spring-assisted terminals that provide more permanent and secure conductor connections.

As the terminal screw is tightened, pressure is generated against the conductor and causes the split-terminal body to expand and elliptically deform the spring ring around the terminal. Since the spring ring wants to return to its original circular shape, it exerts a constant pressure against the terminal conductor, pushing them together. This constant spring pressure on the screw and conductor helps to compensate for strand settlement and conductor yield, while providing superior resistance to the effects of vibration, shock, and thermal cycling.

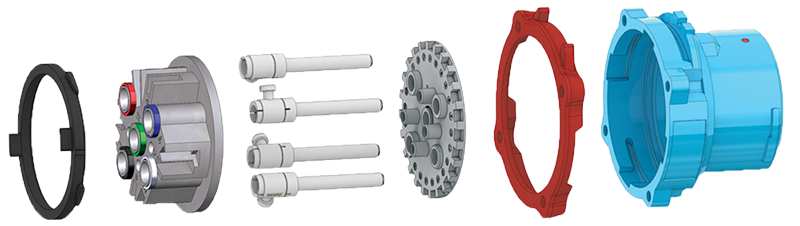

Control, Monitor, Communicate

MELTRIC Switch-Rated plugs and receptacles are available with optional auxiliary/pilot contacts that allow users the convenience and flexibility of controlling auxiliary equipment, monitoring process parameters, and/or communicating alarms without the need for secondary connectors. The larger models are available with up to 6 auxiliary contacts.

MELTRIC DS and DSN Switch-Rated plugs and receptacles achieve their rated watertightness simply by connecting the plug and receptacle. There is no need to thread on or turn watertightness rings as is required on many pin and sleeve devices. DSN Series devices provide Type 4X and IP69K/IP69 watertightness, while the DS Series provides Type 3R as standard or Type 4X as an option.

Making safe connections is easy even on in-line and cord drop applications and even for large amperage devices. Optional finger drawplates are available for 20 to 100A devices and drawbar mechanisms are provided standard on the larger DS100, DSN150 and DS200 devices.

MELTRIC provides a wide variety of mounting angles, handles, and wall boxes allowing its devices to be used in wall box receptacle, in-line, direct motor mounted, panel mounted, cord drop, flexible conduit and other applications. This makes it easy to locate a disconnect switch within line-of-sight of the powered equipment and helps avoid design and space issues encountered with large wall mounted bladed disconnect switches.

MELTRIC plugs and receptacles are durable and withstand harsh environments, so repairs may never be necessary, but if they are, replacement parts are reasonably priced and readily available. The design allows the changeout of casings, individual contacts, full interiors or other specific parts, avoiding the need and cost of replacing the entire device.

It should be noted that only devices returned to the factory for rebuild will maintain their UL/CSA certification; devices that are field repaired by users do not.