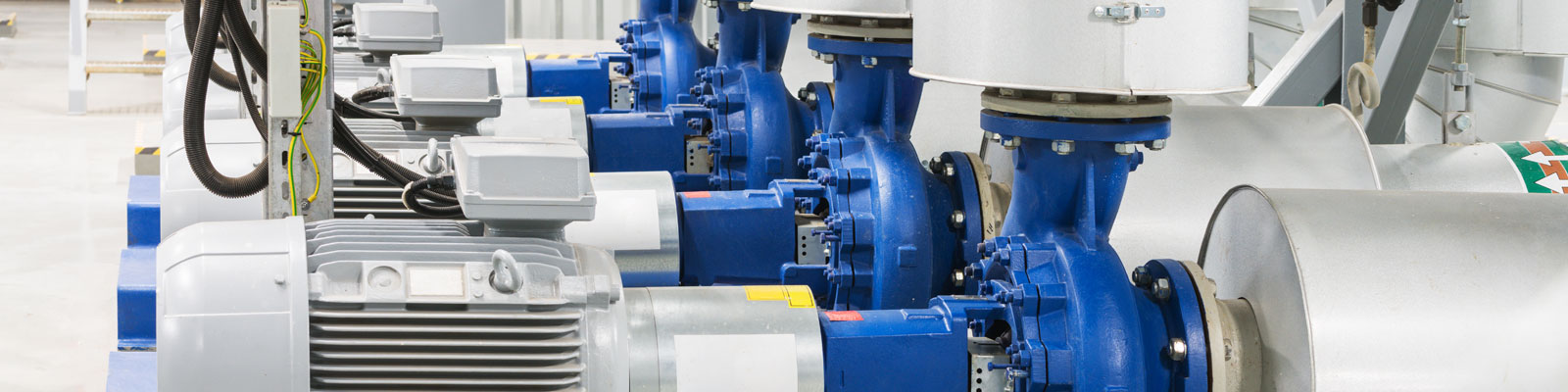

Electric Pump Connections

Simplify Pump Electrical Connections with MELTRIC

Perfect Pump Maintanence with Switch-Rated Plugs and Receptacles

Up to 100 hp or 200 amps

MELTRIC’s switch-rated plugs and receptacles offer an efficient solution for quick pump maintenance, significantly reducing downtime by up to 50% and enabling plug-and-play simplicity.

Advantages of Using MELTRIC for Pump Electrical Connections

A qualified technician can safely disconnect power to the pump simply by removing the plug, which can then be easily locked out to ensure complete safety. Traditional pump servicing methods can be time-consuming and labor-intensive, but with plug-and-play MELTRIC devices, you can cut this downtime by 50% or more.

- Quick and Safe Pump Maintenance

- Reduce Downtime by Up to 50%

- Plug and Play Simplicity

How MELTRIC Enhances Pump Maintenance Efficiency

MELTRIC devices are engineered for durability and versatility, making them suitable for a wide range of pump applications. Their robust construction ensures long-term reliability, even in harsh industrial environments, providing a dependable solution for your facility’s needs.

- No Need for Electricians or Extensive Safety Gear

- Ensures Safety and Reliability

- Versatile and Durable Solutions

Request a Quote | Find a Rep

Try Before You Buy: Test out a FREE MELTRIC Switch-rated plug and receptacle, Today!

Applications/Solutions

Pasteurizers

Portable Pump Cart

Pump Connections

Outdoor Pumping Stations

Pump on juicer machinery

Electric Pump Connections Benefits

Safe

Safely Make/Break Motor Connections, Even During Overloads

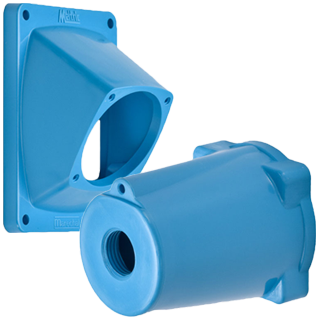

MELTRIC Switch-Rated plugs and receptacles are designed and rated to make and break motor loads in complete safety while providing users with significant protection in the event of overloads or short circuits. Operators do not require special protective equipment or training to make and break connections with MELTRIC Switch-Rated devices. Overload testing includes 50 opening and closing operations performed at 600% of full load motor ampacity with a power factor of 0.5 or less.

All hp-rated MELTRIC devices are rated to close into and withstand short circuit currents up to 100kA in circuits protected with RK1 fusing. Note: Although Switch-Rated plugs and receptacles are rated to safely make and break motor loads, they are not rated or intended for continuous use as a motor starter. More...

Line-of-Sight Disconnect

Easily Locate Line-of-Sight Disconnects Using Mounting Options

Sections 430.102 – 430.109 of the National Electric Code require approved disconnecting means to be located in a readily accessible location within sight of the motor and driven equipment. Since MELTRIC Switch-Rated devices are UL/CSA listed for "Motor Circuit Disconnect Switching" and "Branch Circuit Disconnect Switching," they are an approved line-of-sight disconnect switch. They are a simple and convenient way to meet this NEC requirement.

MELTRIC Switch-Rated plugs and receptacles are available with numerous handles, mounting angles, wall boxes, and other accessories. They may be used as in-line connectors or may be mounted on walls, panels, equipment, or even directly on the motor. This flexibility makes it simple to locate disconnects where they are easily visible and convenient to use. More…

Pre-Wire Replacement Motors

Reduce Improper Motor Rotation with Pre-wired Replacements

Replacement motors that are pre-wired and tested with appropriately phased receptacles in the service center will automatically provide the desired direction of rotation when connected (plugged in) on site. Pre-wiring and testing eliminates the need to jog the motor and avoids additional downtime and production problems resulting from improper rotation.

Auxiliary Contacts Monitor Motor Conditions

Monitor Motor Temperature Using Built-in Auxiliary Contacts

Optional integral auxiliary contacts can be used to communicate motor temperatures back to a control center so preventative maintenance can be performed before motor a failure occurs.