Protection for Most Gas and Dust Environments

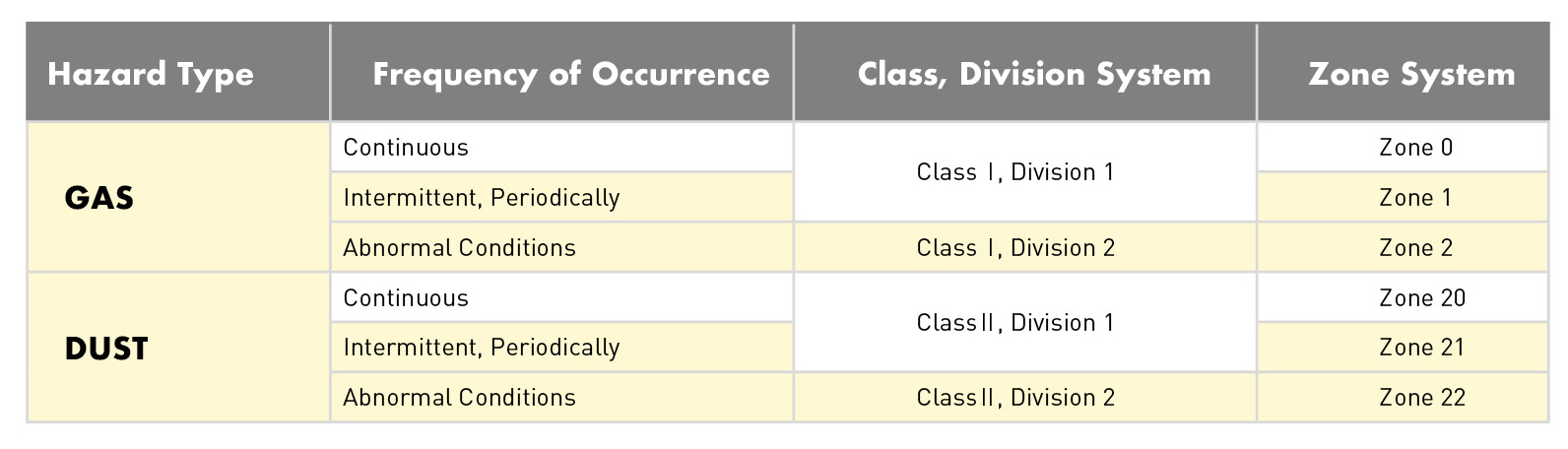

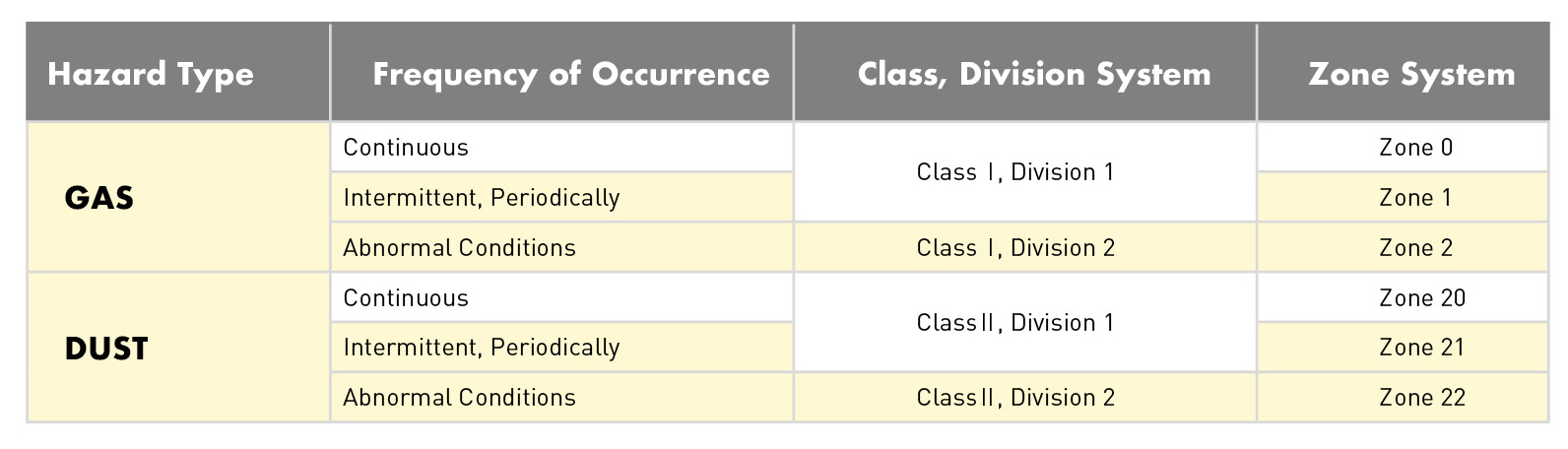

MELTRIC offers a wide range of Hazardous Location products that provide connection solutions for most installations in gaseous and dusty environments. With Zone 1 & 2, Zone 21 & 22 and Class 1 and Class 2, Division 2 products available, they cover any environment other than those with an almost continuous presence of the hazard.

Models are available with cCSAus certifications from 20A to 250A in 3 phase devices and up to 600A in single pole devices. ATEX and IECEx configurations are available from 20A to 125A in 3 phase devices and up to 680A in single pole.

Some are compact and lightweight yet very durable poly devices, others are larger robust metal devices and all feature spring-loaded butt contacts and either silver-nickel or silver contact surfaces to provide consistently superior electrical performance and long operating lives.

The protection methods, ratings and certifications vary by product line. See the range summaries and features descriptions below or click here for a comparison table showing all the ranges.

Hazardous location multipin products are covered separately in the Hazardous Location Multipin section.

Hazardous Location Brochure

Download our Hazardous Location brochure to read more about the solutions MELTRIC offers for electrical connections in hazardous locations.

Benefits

Superior Electrical Performance

Spring-loaded silver-nickel butt style contacts and spring assisted terminals provide safe and reliable low resistance connections. More…

Installation Flexibility

A variety of handles, mounting angles and wall boxes are available for all devices making it easy to configure the product for any application. More…

Ease of Operation

Available draw mechanisms and push button disconnection make operation simple. More…

Power and Control in One Connection

Optional auxiliary contacts help users reduce cost and improve efficiency. More…

HP Ratings Help Meet Code Requirements

With ratings up to 100 hp, it is easy to find an appropriate model to serve as a convenient line of sight disconnect for most motor applications. More…

Added Security of Pad-Lockable Connections

Eliminate concerns over unauthorized connections with available options and accessories. More…

Ranges

- cCSAus and ATEX/IECEx configurations

- Class I: Zones 1 & 2, Division 2

Class II: Zones 21 & 22, Division 2

- 20A to 60A

- .75 - 20 hp

- Current interrupting (AC)

- IP66/IP67 environmental ratings

- 25kA close and withstand short circuit ratings

- Compact size, poly casing

- cCSAus and ATEX configurations

- Class I: Zones 1 & 2, Division 2

Class II: Zones 21 & 22, Division 2

- 20 A, 600 VAC

- .75 - 10 hp

- Current interrupting (AC)

- 25kA close & withstand short circuit rating

- IP66/IP67 environmental ratings

- Metal casings

- cCSAus Listed

- Class I, Division 2 Groups ABCD, T6

Class I, Zone 2 IIC

- 20 to 250A, 600 VAC

- 20 to 200A, 250 VDC

- .75 – 100 hp (AC only)

- Not for current interruption

- Type 4X environmental ratings

- Poly and metal casings

cCSAus

- Class I, Zone 1 IIC

- Class I, Division 2 Groups ABCD

- Class II, Division 1 Groups EFG

- Class III, Division 1

- Up to 600 A, 600VAC

- IP65/IP66 environmental ratings

ATEX/IECEx

- Zones 1 & 2 and 21 & 22

- Up to 680 A, 1000VAC, 1500VDC

- IP65/IP66 environmental ratings

- ATEX/IECEx

- Ex II 2 G D Ex de IIC tD A21

- Zones 1 & 2 and 21 & 22

- 20 – 125A, 750 VAC

- IP65 or IP65/IP66 environmental ratings

- ATEX/IECEx

- Zone 1 & 2

- Zone 21 & 22

- 5 A, 250V non-current interrupting

- IP66/IP67/IP69 Water and Dust Protection

- Glass Reinforced Thermoplastic Casing

Key Features

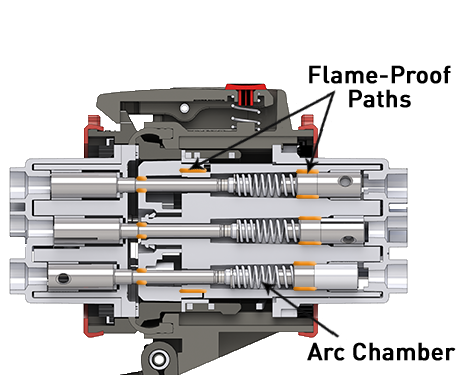

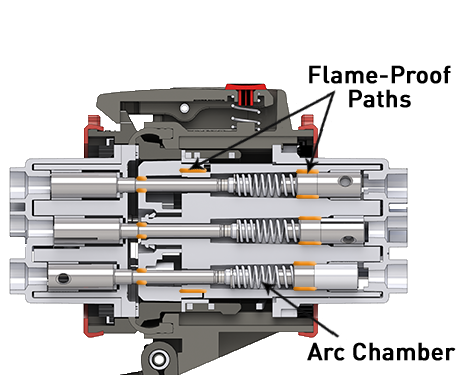

Flame-Proof Arc Chambers and Increased Safety Terminals

DXN and DXA devices are rated for current interruption and can be operated under load in a hazardous environment, if required, so they need an appropriate means of protection to eliminate the explosion hazard. This is accomplished through specially-designed flame-proof arc chambers.

The arc chambers are sized to minimize the amount of atmospheric gas or air/dust mixture that may ignite during arcing and are built to contain this internal mini-explosion and withstand the pressure that it generates. The length and width of the flame-proof pathways are precisely designed to provide for the effective dissipation of the pressure, while also ensuring that the arcing and internal ignitions of gases or air/dust mixture in the arc chamber are totally isolated from the surrounding atmosphere.

To meet Zone 1 certification requirements, DXN and DXA devices also use special terminals designed to provide increased safety against potential arcing in the termination area.

Locking Means to Prevent Unplanned Disconnection

All Zone 2 product receptacles feature a standard screw-type locking pawl. The required procedure of tightening the locking screw prevents actuation of the pawl/release button and thus locks the plug to the receptacle. The screw must be loosened with an Allen wrench to unlock the latching system before the plug can be removed. This ensures against unintended disconnection.

For additional security, a lockout hole is also provided on the receptacle which enables users to either padlock the connected plug to the receptacle or to padlock the receptacle lid closed to prevent insertion of a plug. This is accomplished by inserting a 5/16” shank diameter lock or optional locking pin (and user lock) through the pawl to prevent its actuation even if the locking screw has been loosened.

Mechanical/Electrical Interlock Prevents Operation Under Load

SPeX devices are equipped with an interlock system that requires the plug to be inserted and latched in place before the twist ring can be rotated to the ON position to complete the pilot circuit controlling the power. While the device is in the ON position, the latch release is deactivated so the plug remains locked into the receptacle and cannot be removed.

In order for the plug to be removed, the twist ring must first be rotated back to the OFF position, breaking the pilot circuit and thus deenergizing the power circuit. The plug can then safely be removed by depressing the latch release button and withdrawing it from the receptacle.

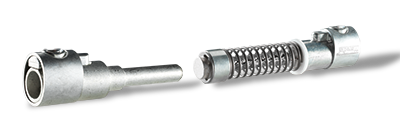

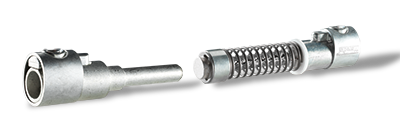

Spring-Loaded Butt Contacts Provide for Thousands of Consistent and Reliable Connections

MELTRIC plugs and receptacles use spring-loaded, butt-style contacts similar to those used on contactors and switchgear. Their end-to-end mating provides a stable connection. The spring-loading delivers optimal contact pressure, and the integrity of the electrical connection is maintained over thousands of operations.

- Spring-loaded butt contacts automatically compensate for manufacturing variations, eliminating contact mating and connection quality problems caused by the dimensional variations of other contact designs.

- End-to-end mating eliminates the effects of wear inherent with sliding contacts.

- Consistent spring pressure eliminates overheating caused by poor contact force. The performance and design advantages of spring-loaded butt contacts make them a superior choice for providing consistently safe and reliable connections.

Silver-Nickel Contact Material Provides Superior Conductivity

MELTRIC uses solid silver-nickel contact surfaces on its Switch-Rated plugs and receptacles. The contacts’ 85% silver and 15% nickel composition combines the durability of nickel with the excellent conducting properties of silver. Silver-nickel contacts provide significant advantages over the brass materials used on most other types of plugs and receptacles:

- Silver-nickel maintains low contact resistance and superior electrical properties even after oxidation and tarnishing.

- Silver-nickel withstands arcing very well and only welds at extremely high pressure and temperature.

- The hardness of nickel gives the silver-nickel contacts excellent wear resistance.

- Silver-nickel performs well in and withstands wet and corrosive environments.

The combination of silver-nickel contacts with a spring-loaded butt-style design makes the contacts ideal for repetitive operation and, in the case of the DXN and DXA, also for making and breaking connections under load.

Limitations of Brass as a Contact Material

- Brass is not arc resistant, so it is not suitable for repeated making and breaking under load.

- Brass is a soft material and wears rapidly, degrading the operational characteristics of the contact.

- Brass oxidizes easily, preventing it from performing well in wet or corrosive environments.

- The contact resistance of brass increases rapidly due to tarnishing that occurs during normal use.

Lockout or Lock Together

DXN, DXA and all Zone 2 devices include standard provisions on the plug that allow users to perform lockout/tagout by simply inserting a lock through an existing hole on the device. The user only needs to provide the lock – no additional mechanisms are required.

Simple lockout provisions for the receptacle are also provided standard on Zone 2 devices and are available as an option on DXN and DXA models. They allow the lid to be locked in the closed position to prevent the insertion of a plug. An available locking pin fits snugly in a circular opening through the pawl and blocks it from operating. Various sizes of locks and lockout hasps can be used with the locking pin to complete the lockout.

The lockout provision on the receptacles can also be used to lock the plug and receptacle together. This can be an important consideration in public or other critical areas where it is important to prevent unauthorized disconnections.

Spring-Assisted Terminals Provide Superior Conductor Connections

On traditional plugs and receptacles, the loosening of terminal screws is a common cause of failure. MELTRIC devices have patented, spring-assisted terminals that provide more permanent and secure connections to circuit wiring.

As the terminal screw is tightened, pressure is generated against the conductor and causes the split-terminal body to expand and elliptically deform the spring ring around the OD of the terminal. Since the spring ring wants to return to its original circular shape, it exerts a constant pressure against the terminal and conductor, pushing them together. This constant spring pressure on the screw and conductor helps to compensate for strand settlement and conductor yield, while providing superior resistance to the effects of vibration, shock, and thermal cycling.

MELTRIC hazardous location plugs and receptacles achieve their rated watertightness simply by connecting the plug and receptacle. There is no need to thread on or engage additional watertightness rings as is required on many pin and sleeve devices. DXN and DXA devices provide IP66/IP67 protection, Zone 2 devices provide Type 4X, and the SPeX and DX series provide IP65/IP66.