Portland Community College Chooses MELTRIC due to its Superior Safety and Plug-and-Play Capability

MELTRIC Switch-Rated plugs and receptacles provide power to 60 different welding workstations throughout the welding lab.

MELTRIC Switch-Rated plugs and receptacles are designed and rated to make and break motor loads in complete safety while providing users with significant protection in the event of overloads or short circuits.

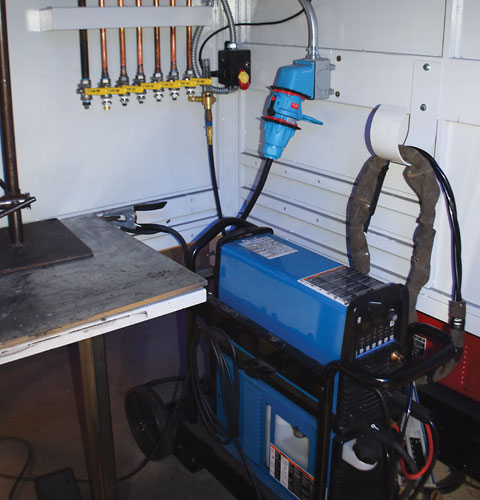

Welding workstations equipped with MELTRIC Switch-Rated plugs and receptacles.

Instructors and students can safely change out welding equipment due to plug-and-play simplicity.

Portland Community College Chooses MELTRIC due to its Superior Safety and Plug-and-Play Capability

Portland Community College is the largest post-secondary institution in Oregon serving approximately 80,000 full- and

part-time students. The Welding program offers 15 different degrees and certificates. Through a community bond, the Rock Creek Campus had the opportunity to rebuild its welding lab and fabrication bay from the ground up. An important consideration in the lab rebuild was to ensure student safety but at the same time provide Portland Community College the flexibility to configure the lab to meet the demands of their student workload. When working through these considerations, Portland Community College was introduced to MELTRIC.

Electrical shock through an arc flash incident is one of the inherent risks associated with welding. MELTRIC Switch-Rated plugs and receptacles eliminate an arc flash hazard. They are a combination plug, receptacle, and disconnect switch in one device. They feature a built-in switching function that ensures the contacts are safely de-energized before the welding machine plug can be withdrawn.

For Matt Scott, who has been the welding instructor at Portland Community College for the past 28 years, the superior safety of MELTRIC plugs and receptacles was the most important factor in choosing MELTRIC. Matt was the welding instructor in the mid-2000s when an electric shock incident happened with a 480 V pin and sleeve device/disconnection box. A student attempted to disconnect the device and it resulted in the student being thrown off his feet and he remained on the ground for around 5 minutes. The student was taken to the hospital via ambulance. Fortunately, the student escaped without major injuries, however, Matt’s perspective on safety changed that day.

Matt claims that when he was first introduced to MELTRIC it was “love at first sight.” Matt recognizes the push-button/quick break disconnection technology and the dead-front safety shutter as the primary safety features he values. “The idea that you can push a button, it pops, and is safe to twist out is pretty incredible.”

MELTRIC Switch-Rated devices disconnect the circuit simply by pushing the OFF button. This automatically breaks the

connection and ejects the plug to the OFF position. The plug can then safely be removed by rotating it 30° to withdraw

from the receptacle.

MELTRIC Switch-Rated plugs and receptacles have been used for decades in the welding industry including training facilities because of their switch rating. They provide unique safety features because they combine the safety and functionality of a disconnect switch with the convenience of a plug and receptacle and are ideally suited for safely making and breaking electrical connections on portable welding equipment.

To eliminate the risk of arc flash and electric shock, the receptacle seals all the live parts in an enclosed arc chamber shrouded by a safety shutter, consequently offering the highest level of safety in the welding industry. For that reason, staff and students who operate MELTRIC devices are never exposed to arcing because the plug is always de-energized before it can be removed from the receptacle. The separation of the plug and receptacle provides visual verification of de-energization, so voltage testing is not required. The receptacle’s safety shutter prevents exposure to live parts and thus simplifies NFPA 70E compliance while eliminating the need for cumbersome PPE to operate the plug/receptacle. This provides unique plug-and-play simplicity for MELTRIC devices.

Aaron Gardner, Instructional Support Technician, said, “We saw right away that MELTRIC plugs and receptacles were definitely an upgrade from what we had in the shop before, both safety-wise and ease-of-use. Once we got an idea of how they worked, we were really impressed with the technology, and we wanted to upgrade all the receptacles and plugs in the shop with MELTRIC.”

Plug-and-play simplicity allows any qualified worker to quickly connect and disconnect welding equipment. Specially trained maintenance technicians are not required for load making or breaking. This means welding instructors or even students can safely change out welding equipment. With their focus on safety and plug-and-play capability, both Matt and Aaron insisted that MELTRIC devices be installed throughout the welding lab and fabrication bay. With 120 to 150 students per term, the ability to safely change out a machine based on student load is essential.

Currently, Portland Community college has 84 MELTRIC devices installed in their Rock Creek facility. Most of the devices are DSN 60s (60 Amp, 3 Phase, 480 VAC configurations) installed on 60 different welding workstations. The remaining devices in the facility are DSN 30s (30 Amp, 3 Phase, 208 VAC configurations).

Based on the safety, performance, and simplicity of MELTRIC devices there are now plans to install MELTRIC devices into the welding labs at Portland Community College’s Columbia County Center.