Switch-Rated Motor Plugs Grow Maintenance Efficiencies at Seed Production Facility

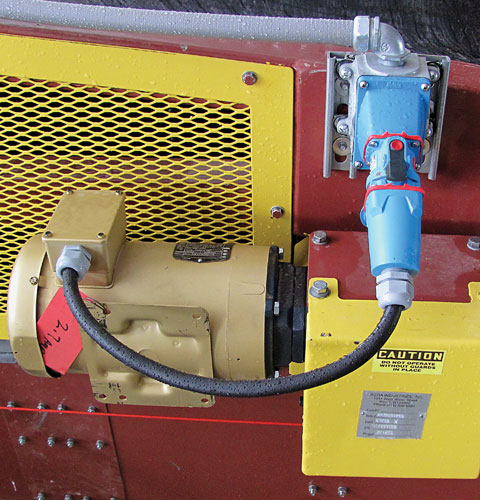

Installing a MELTRIC Switch-Rated plug and receptacle between a motor connection box and the power line feed eliminates all hardwiring tasks during motor changeouts. Load breaking is performed in seconds by pushing the pawl on the plug’s casing.

Add optional auxiliary (pilot) contacts to Switch-Rated connec-tors for equipment control, monitoring, and communications features.

MELTRIC Switch-Rated plugs and receptacles positively impacted motor installation, maintenance, and changeout productivity at the Remington Seeds production facilities in Remington and Francisville, IN. The sites are two of several Remington Seeds facilities that produce, condition, and package high-quality corn, soybean, and wheat seed.

MELTRIC plugs are used as motor connectors for conveyors, huskers, shellers, dust systems, and hydraulic power units. MELTRIC Switch-Rated devices improve maintenance efficiency by reducing maintenance downtime on the motor-driven equipment.

At the heart of the maintenance efficiency improvements is the plug and play capability of MELTRIC Switch-Rated connectors. They are UL approved for motor and branch circuit disconnect switching, and are constructed with an integral switching mechanism that ensures the safe make or break of live connections. Additionally, due to the Switch-Rated plug design, the contacts are electrically dead before the plug can be removed from its receptacle, ensuring user safety. This eliminates the need for expensive interlocks or the mounting of a local disconnect switch. Because there is no electrical risk to workers when connecting or disconnecting a MELTRIC Switch-Rated plug and receptacle, an NFPA 70E-defined “normal condition” is maintained without the need to suit up in PPE.

Dead-front construction ensures protection from live parts and arcing and the disconnected plug provides visual verification of deenergization. The plug features a built-in provision in the plug shroud for fast and easy lockout/tagout.

The impact on downtime for motor changeouts or any task requiring motor deenergization has benefitted the Remington facilities where MELTRIC Switch-Rated plugs and receptacles are installed on production equipment. According to Greg Schneider, the electrical contractor who performs the installation and maintenance work at the Remington and Francisville facilities, “Motors can be changed out quickly and safely with MELTRIC plugs. They are easy to install, and there is no need to mount a disconnect switch nearby. They meet the code requirements for a ‘line of sight’ disconnect switch. As an ‘all in one’ plug, they’re a safe and flexible connector ideally suited for fast motor changeouts.”