Case Study - Spray Dynamics Group - Heat and Control, Inc.

Issue date: 17 January 2019

If you’re a snack food aficionado, there’s a good chance the delicious cheesy, salty, spicy, or sweet seasoning left on your fingers after digging into a snack bag, are resultant of a research and development session at Spray Dynamics.

The company, which set down roots in the town of Costa Mesa, California in 1952, got their start designing and building liquid applicators to spray release agents into baking molds and pans. Expanding their operations to the snack food industry in 1970, the company designed and built specialty equipment for that market. Between the 1980s-2000s, Spray Dynamics grew again (including relocating to St. Clair, Missouri in 1993)—adding bakery, cereal, and other food and non-food markets. Today, they design and build new equipment lines for full-system coating, liquid and dry applications, tumbling machines, mixers, dryers/roasters, and more. Employed by some of the biggest manufacturers in the world, Spray Dynamics’ equipment is ubiquitous with innovation and quality.

They’re ideal for wet, washdown environments.

Company Expansion

In 2011, Spray Dynamics joined Heat and Control, an international powerhouse known for creating innovative, technologically-advanced food (and other industry) processes, systems designs, and manufacturing equipment. Today, the company is known as the Spray Dynamics Group of Heat and Control, Inc.

The Spray Dynamics Group of Heat and Control, Inc. recently opened a 108,000-square foot state-of-the-art engineering and manufacturing facility in Union, Missouri, just a short distance away from their previous location in St. Clair. Here, the company uses the latest technology to design, fabricate, and test turnkey systems before shipping them to customers. The new facility was built with a customer-centric design, adding a world-class demonstration/technical center and visitor hosting quarters. Specially-designed video conference rooms are used to meet with offsite customers, provide training sessions, and give project updates. The new technology helps Heat and Control keep their customers informed and on the cutting edge of new processes and products.

fast and easy

Customer Relationships are Priority One

The Spray Dynamics Group of Heat and Control, Inc. prides themselves on their extensive industry experience, flexible custom solutions, innovative designs, high-quality equipment manufacturing, and most importantly, their excellent customer relationships. General Manager, Lucas Bell explains, “Beyond our high-quality equipment, what sets us apart from the competition is that each person on our team remembers that our products and services mean success for our customers. Each piece of equipment we provide, each parts order we fill, each service visit we make, every email we send, is done as if it is the most important thing we do.” He adds, “Our equipment’s performance may get us a new customer, but it’s our communication and support after the sale that has given us our many long-term customers.”

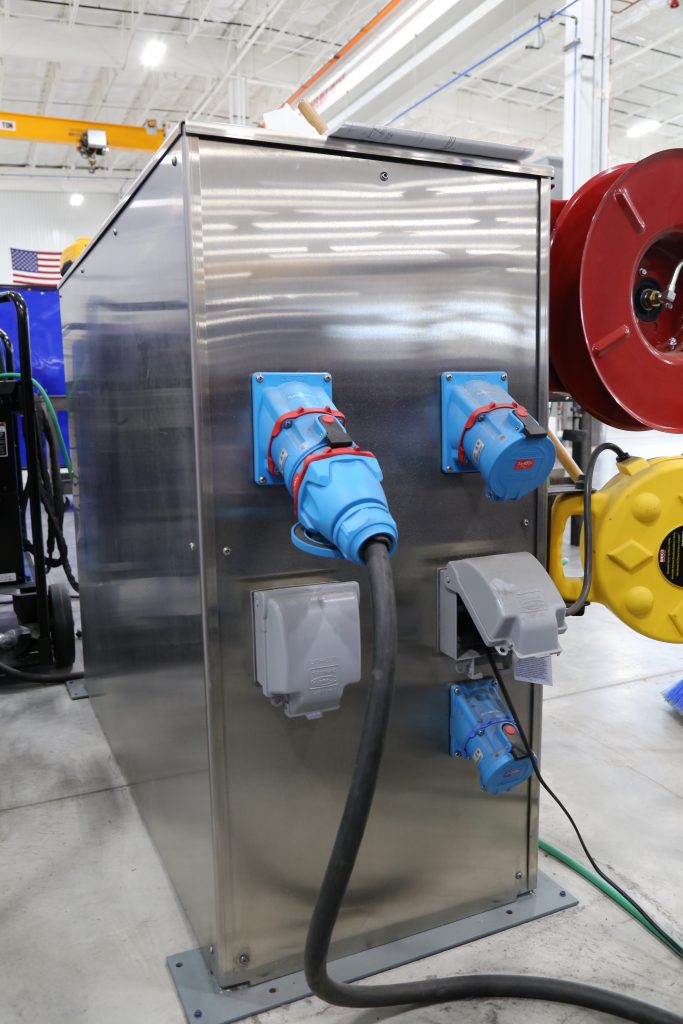

This strong commitment to customers is one of the primary reasons the Spray Dynamics Group of Heat and Control, Inc. chose MELTRIC to supply plugs and receptacles for their original equipment manufacturing (OEM) products. Service/Controls & Integration Manager, Brian Haynes says, “We sell high-quality products and believe we should supply our customers with high-quality and safe means to connect and disconnect our equipment.” He continues, “Adding MELTRIC plugs and receptacles to our OEM products provides the end user with safer, faster equipment disconnects, while dramatically reducing the UL disconnect footprint on our equipment.”

MELTRIC Devices are Cost-Effective and Safe

In addition to partnering on Heat and Control, Inc. manufacturing equipment, MELTRIC plugs and receptacles are installed in every area of the new plant. Haynes remarks, “We have used pin and sleeves and twist-locks in the past. We value MELTRIC devices as cost-reducers; they eliminate the need to constantly replace damaged and faulty equipment.”

MELTRIC plugs and receptacles power everything from welders and motors, to cord drops, test lab equipment, and other machinery across the facility. The Spray Dynamics Group of Heat and Control, Inc. chose MELTRIC DSN Switch-Rated plugs and receptacles with DECONTACTOR™ technology for use both in the plant and on their equipment.

MELTRIC Switch-Rated devices provide complete deenergization with the push of a button; there’s no need to add expensive disconnects. A built-in arcing chamber and dead-front safety shutter ensure workers and customers will not be exposed to arc flash hazards or live electrical parts. MELTRIC’s corrosion-resistant spring-loaded, silver-nickel, butt-style contacts provide superior electrical connectivity. Type 4X/IP69K environmental ratings and ingress protection ensure watertight connections; ideal for wash down environments.

MELTRIC DSN Switch-Rated plugs and receptacles are UL/CSA rated for motor and branch circuit disconnect switching. They are NEC ‘line of sight’ compliant and are ideal for fast, easy, plug and play equipment changeouts. MELTRIC devices include a built-in provision for easy lockout/tagout.

Haynes continues, “We value the ability of MELTRIC devices to give us plug and play functionality without any worry of arc flash or shock hazards to our employees within our facility. The quality, reliability, and product capability of MELTRIC plugs and receptacles is second to none in the connector industry.”

Learn More

Click here to learn more about Spray Dynamics Group of Heat and Control, Inc.

Franklin, Wis.-based MELTRIC manufactures a comprehensive line of industrial plugs and receptacles, including UL/CSA Switch-Rated plugs and receptacles. Visit meltric.com to learn about our industry-leading products and our continued emphasis on safety and quality.