MELTRIC DXNs Simplify Purina Mill’s Motor Maintenance

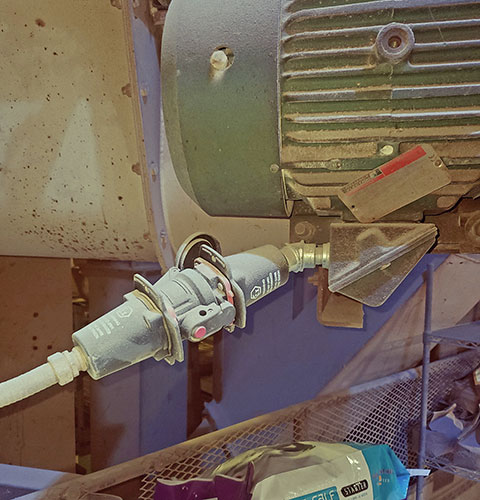

Purina Mill uses MELTRIC DXN Hazardous Location plugs and receptacles for motor connections throughout their plant. Plug and play connections simplify motor maintetnance and changeouts.

MELTRIC DXNs provide safe, reliable connections in Hazardous Locations where dust and gas are present. DXNs are rated for use in Div 2, Class I and II, Zones 1 and 2, 21 and 22.

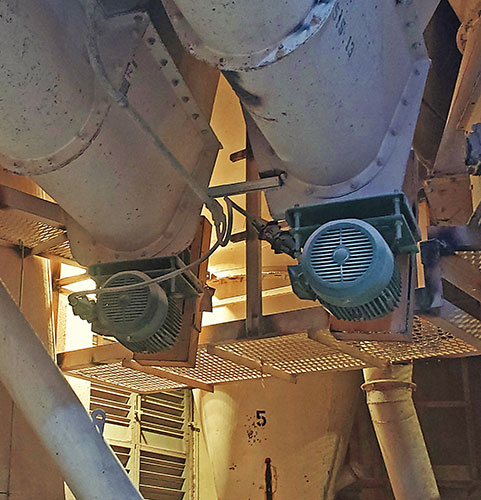

With the DXNs’ direct motor mounts, Purina Mills saved more than $75,000 on electrical boxes and wiring costs. MELTRIC DXNs provide convenient mounting options, even in areas with limited space.

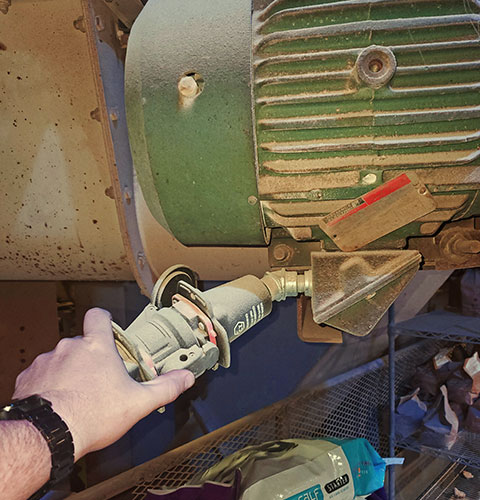

Safe, push-button deenergization simplifies motor and equipment changeouts. This improves efficiency and minimizes downtime.

“We haven’t had a single fault with any of the MELTRIC products since we’ve put them in. They all work, they work great, and they stay clean because they are totally enclosed. I like the products.”- Joey Foster, Plant Maintenance Manager and Feed Safety Supervisor, Purina Mills

Airborne dust thinly coating equipment and motors is not uncommon at the Purina Mill in Lubbock, Texas. The plant, which has been in operation for more than 20 years, produces 150 stock product types of high-quality, commercial-grade animal food, including 120,000 tons of pellets and 156,000 tons of mixed feed, annually.

Joey Foster, Plant Maintenance Manager and Feed Safety Supervisor, is responsible for keeping motors and equipment well-maintained and operational, while protecting his employees from hazards. A plant veteran with seven years experience, Foster and his team depend on MELTRIC DXN Hazardous Location plugs and receptacles for safe, efficient motor connections. DXNs are CSA, ATEX, and IECEx certified for use in Zones 1 and 2 (gas) and Zones 21 and 22 (dust). The devices are safe for circuit interruption and are available from 20-60A, up to 600 VAC, and include horsepower ratings from .75-20 HP.

VFDs Give Way to Local Disconnects

In the past, the plant’s motor connections, which power conveyors, feeders, mixers, and other equipment, were connected to variable frequency drives (VFDs). A single VFD could control 10 different motors. When motor maintenance needed to be performed, all of the motors attached to a VFD had to be shut down, causing disruption to the processing operation.

Several years ago, the company wanted more efficient motor connections and decided to discontinue VFD connections in favor of local motor disconnects. While the idea worked in theory, Foster expected complications. Each local disconnect required a 12 x 12 x 6 electrical box, as well as brackets, hardware, and wiring. Motor connections were often located in tight spaces; there wouldn’t always be enough room for the boxes and wires. Additionally, costs for the materials and installation were astronomical. Foster knew there had to be a better solution.

MELTRIC DXNs Provide Motor Mount Solutions

After researching hazardous location motor connections online, Foster was interested in learning more about MELTRIC products. He contacted an electrical distributor who reached out to a local MELTRIC Sales Representative. Over a phone call, Foster and the MELTRIC Rep discussed MELTRIC solutions for motor connections. The MELTRIC Rep then brought Foster a product sample. Foster was impressed by the ease and simplicity of the device’s operation and design, as well as the safety the DXN affords his maintenance crew.

MELTRIC DXN Hazardous Location plugs and receptacles feature an arc isolation chamber and arc-extinguishing flamepath that safely contain arcing within the chamber, eliminating arcing hazards at disconnection. A dead-front safety shutter prevents access to live contacts, further enhancing user safety.

The compact, lightweight MELTRIC DXNs could be mounted directly to the motors, eliminating the need for boxes and additional wiring. This simplified installation saved the company more than $75,000 over the cost of other local motor disconnects.

MELTRIC Simplifies Motor Changeouts and Preventive Maintenance

Today, Foster uses MELTRIC DXN Hazardous Location plugs and receptacles for all of the motor connections throughout the facility. He continues to save the company money and time because he and his team no longer need to call an electrician to unwire or re-wire the motors for service. Foster said, “If you use this plug, you don’t need to have an electrician to replace the motor,” he continued, “all the technician has to do is unplug it, change the motor, and plug it back in.”

Using the DXN push-button disconnect, maintenance crew members don’t need to wear special PPE, perform additional voltage testing, or walk to a control room to shut down power and lock out the connection. They simply push the button on the pawl of the DXN to safely break the circuit and completely deenergize the connection. Once the plug ejects from the receptacle, a tech can pull them apart and add a lock or hasp to the built-in provision in the plug shroud to quickly lock and tag out the motor. After maintenance is complete, the tech removes the lock and reconnects the plug and receptacle. If a motor needs replacement, the tech deenergizes the circuit using the push-button disconnect, swaps out a pre-wired motor, and plugs it in. Motor changeout complete. According to Foster, since installing the DXNs, motor lockout and changeout efficiencies have improved by 15 and 40 percent, respectively.

The simplified connections also assist with preventive maintenance. Foster and his team no longer have to schedule downtime with production managers. They can disconnect the motor on a production line that isn’t being used, perform the maintenance task, and put the motor back online. If the Control Room team needs the line back up while the maintenance is being performed, the tech simply reconnects the plug and receptacle and the motor is ready for production. Foster remarked that the entire process using MELTRIC DXNs has “really been a blessing.”

Foster highly recommends MELTRIC DXN plugs and receptacles and advocates for their use with Purina engineers and maintenance supervisors looking to simplify motor connections at other facilities. The rugged durability and high performance of MELTRIC DXNs, even in the dusty environment of an animal food processing plant, has served Foster and the company well.

Learn More

Visit meltric.com to learn more about MELTRIC DXN Hazardous Location products, as well as our full line of safe, reliable, industrial plugs and receptacles.

Plug in to safety with MELTRIC.