DECONTACTOR™ Technology

- Gasket color confirms voltage rating

- OFF button quick break technology releases the energy and ejects plug to off position in 15 milliseconds

- Automatic watertightness up to Type 4X/IP69/IP69K

- Dead-front safety shutter prevents user access to live parts

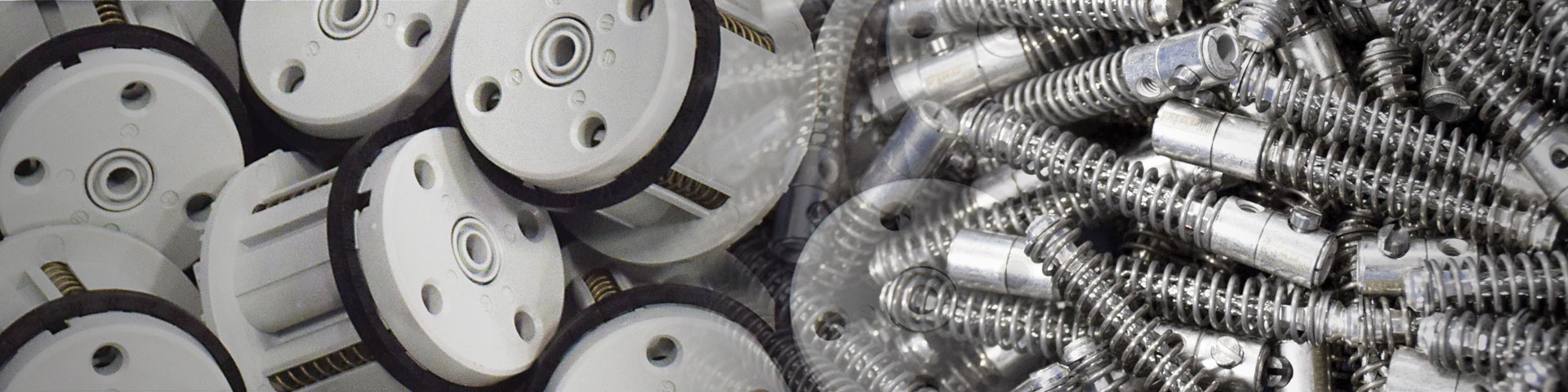

- Silver-nickel contacts provides excellent electrical conductivity and performance

- Enclosed arc chamber eliminates arc flash at disconnection

- Unique keying positions prevents device mismatching

- Spring-loaded butt-style contacts ensures optimal contact force and excellent performance

- Fiberglass reinforced thermoplastic poly casing offers impact, corrosion, and UV resistance

- Spring-assisted screw terminals keep connections tight without frequent re-tightening

What is DECONTACTOR™ Technology?

A MELTRIC Decontactor™ is a specialized electrical connector with push-button circuit disconnection that combines the safety and functionality of a disconnect switch with the convenience of a plug and receptacle in one device.

MELTRIC DECONTACTOR™ Technology allows our Switch-Rated plugs and receptacles to be safely connected and disconnected under full load, up to 200A and 100 hp, in wet or dry conditions.

What is Different about a Switch-Rated Device?

Switch-Rated plugs and receptacles have different capabilities than standard plugs and receptacles. They combine the function of a disconnect switch with the convenience of a plug and receptacle. Switch-Rated plugs and receptacles are UL/CSA listed for “Branch Circuit Disconnect Switching” and/or “Motor Circuit Disconnect Switching.” Standard pin and sleeve, twist lock, and straight bladed plugs and receptacles are not.

To achieve their ratings, Switch-Rated plugs and receptacles are evaluated and performance tested in accordance with UL Subject 2682, the UL Standard created specifically for Switch-Rated plugs and receptacles. The requirements are naturally much more rigorous than for standard plugs and receptacles.

Key performance tests are summarized in the table below.

|

UL Subject 2682 – Performance Test Requirements |

|

|

Voltage Withstand |

3000 VAC for 1 minute |

|

General Overload |

50 Operations @ 150% Rated Current (p.f. ≤ 0.80) |

|

Horsepower Overload |

50 Operations @ 600% of Full Load Motor Current (p.f. ≤ 0.50) |

|

Temperature Rise |

< 30°C - Performed on devices already subjected to the overload test |

|

Electrical Endurance |

6000 Operations @ Rated Current and Voltage (p.f. ≤ 0.80) - Performed on devices already subjected to the overload test |

|

Short Circuit - Make |

≥ 10 kA with appropriate fusing |

|

Short Circuit - Withstand |

≥ 10 kA with appropriate fusing |

MELTRIC was the first company to develop and offer UL/CSA Switch-Rated plugs and receptacles and remains the primary innovator in this field.

Today, MELTRIC offers a full line of Switch-Rated plugs and receptacles covering applications from 20 to 200 A and up to 100 hp. Models are available with up to six auxiliary contacts for integral control, monitoring, and signaling connections.

No one beats MELTRIC for Switch-Rated innovation, safety, reliability, and breadth of product line.

Switch-Rated

Workers risk exposure to arc flash when disconnecting standard welding plugs and receptacles. To prevent accidents ...

Multipin

MELTRIC Multipin plugs and receptacles provide power, control, and monitoring capabilities for multiple circuits in ...

Standard Duty

Looking for reliable, safe electrical connections but don't need switch ratings? MELTRIC has your solution! Our ...

High Temp

Can your electrical connections take the heat? Ours can! MELTRIC PNHT plugs and receptacles are designed for use in ...

Direct Current

Safely power up and stay connected with reliable MELTRIC DSDC plugs and receptacles. MELTRIC DSDC devices provide an ...

High Ampacity

MELTRIC UL/CSA listed High Ampacity plugs and receptacles deliver safe, easy-to-install, high-performing electrical ...

Single Pole

MELTRIC Single Pole plugs and receptacles and welding connectors are compact, lightweight, electrical solutions for ...

Power Distribution

Indoor, outdoor, portable, or mounted, MELTRIC has the right industrial power distribution solution for you! For ...

Hazardous Location

Install MELTRIC Hazardous Location devices for Class 1 & 2 Div 2 and Zone 1/21 & 2/22 environments to make your ...

Hazardous Location Multipin

High Ampacity Multipin Standard Duty DC Self-Ejecting High Temp Hazardous Location Hazardous Location ...